|

The Old Goat's Epoxy Boat Repair marine epoxy resin issues Q&A - FAQ Epoxy Page Old Goat - Marine Site |

|

|

The Old Goat's Epoxy Boat Repair marine epoxy resin issues Q&A - FAQ Epoxy Page Old Goat - Marine Site |

|

Marine Epoxy Boat Repair OLD GOAT

FAQ Q&A Guide

Web Email questions and answers on boat repair, coatings and epoxies

You're talking with: Paul Oman, MS, MBA -- Member since 1994: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings) -- Technical Help - not sales talk!

"The Right Epoxy Fixes Darn Near Everything!"

Search the EPOXY-ONLY World Wide Web search engine

for your Epoxy Related Search term

CLICK HERE FOR EPOXY RELATED SEARCHES

Links:

|

The Marine Epoxy Everything Guide Everything from user reviews, repair examples, pricing issues and vendor evaluation tips

Basic No Blush Marine Epoxy Product Page Basic No Blush 12 oz Marine Epoxy sampler Marine Epoxy Catalog page (multiple epoxies) Basic No Blush Marine Epoxy User Reviews / Feedback How To Evaluating Marine Epoxy brands and Vendors Marine Epoxy prices - what it really costs! Marine Epoxy amine blush - what is epoxy Blush? Boat repair examples using Marine Epoxy Dinghy Marine Epoxy boat repair case study Stitch and glue Marine Epoxy construction Progressive Epoxy Polymer's marine web site Massive site of Internet boat links

|

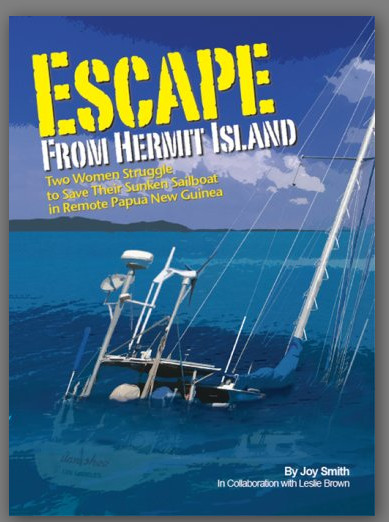

EMERGENCY YACHT UNDERWATER REPAIRA Case Study Using Progressive Epoxy Polymer's Underwater Epoxy - an early version of our WET DRY 700 Underwater Epoxy (BUY NOW). Underwater epoxy for Emergency hull repair - sinking yacht Case Study - now in book form: |

EPOXYGURU.COM website

|

DISCLAIMER: All decisions regarding the suitability of any information/suggestion regarding product selection, surface preparation, and coating application is with the purchaser. Your use of any of these suggestions, procedures, products is at your sole cost and risk. You must make an independent determination whether or not to follow any or all of the suggestions offered. The owners of this site shall not be liable for any injury, loss, damage, direct or consequential damages arising out of the use of its suggestions or comments. |

Email the "Old Goat"

or just call him at 603 435 7199

The "Old Goat" - A.K.A. Professor E. Poxy - M.S. - M.B.A. - epoxy professional since 1994 - Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings) - Yachting Mag. Jr Article writing 1st place winner 1976 - owner of over 30 boats - former sailing instructor - Rochester YC (NY), Offshore Sailing School NYC, Milford CT YMCA, racing experience Milford YC, Humboldt State Sailing Club Arcata, CA, private sailing lessons Galveston Bay, Boat US member since 1988

"You provide outstanding products, and Fantastic Support. Thank You." Brian S. (call 603 435 7199 anytime)

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

Questions asked come from public web sites and forum and personal emails regarding epoxy boat repair and boat building

Question: Aluminum Mast Coatings

Can anyone point to a decent synopsis of the steps to prepare and paint an aluminum mast/boom?

While I've got my boom off the boat and at home in my workshop, I'm thinking I might as well clean it up and give it a paint job to brighten it up.

I've seen masts and booms painted shiny white, and I like that. Right now, both of mine are just bare (oxidized and scuffed) aluminum.

I figure first step is to clean off the oxidation, which I can do with my random orbit sander. But my understanding is there are specific types of primers you have to use for aluminum to get the paint to stick better?

I'm thinking that maybe at the end of this year, I'll have the mast taken down so I can take a good look at the mast step and rigging, and maybe I'll also paint it then.

Thanks!

Answer:

The best fix for reconditioning an aluminum mast is to clean it up and paint with 2 coats of a aluminum filled moisture cured urethane (MCU) which will give the aluminum a 'like new' appearance. MCU coatings are known for their super adhesion. Leave the aluthane aluminum finish alone or topcoat (as in your case) with white enamel paint for the hardware store. Google/Bing the product "aluthane."

Question: Epoxy Fumes - Coating Plywood with Epoxy

Is it safe to use a marine epoxy in the basement and should a respirator be worn while mixing and applying it? Also, when covering the transom, should I apply a coat of epoxy and let it dry and then put the cloth on and wet it out using a foam roller or skip the coat of resin and just put the cloth on the bare plywood and then wet it out.

Answer:

Regular marine epoxies, such as Basic No Blush (tm) or Premium No Blush (tm) have no solvents or fumes (zero VOC). The part B can develop a hash ammonia spell when newly opened after being stored for a while, but that smell will quickly vanish. So no fumes issue with most epoxies.

As far as fiberglassing plywood, either approach is acceptable. Personally I like coating the wood first with solvent thinned epoxy (make your own, or a product like ESP 155) then then applying the epoxy saturated fiberglass after the thinned epoxy is tacky or cured.

Question: How to Treat Hull Blisters

We just pulled our boat out for the first time. Told the yard to clean bottom & apply a coat of A/F paint. Yard called next day, said I needed to look at bottom. It had blisters about the size of a pencil eraser all over it. The guy said it looks like years of bottom jobs were applied on top of the previous coats. Also, the A/F paint was real caulky and flaking off. So, they sandblasted it off to the gelcoat taking the blister tops with it. Now, the yard guy said the boat will have to sit an dry out before they add 3 barrier coats and 1 awlfair coat. He will take moisture readings day 1, day 30, day 60. OK, but here is where I get confused. The boat is out in the open yard, it rains here once or twice a week. I was told that wouldn't hinder the drying time. Does all this sound right?

Answer:

There lots of views about blisters and barrier coats. But, it sounds like the yard sees you as a good source of income. There will always be moisture in the hull and it will go up when you put the boat back into the water. My fix is to pop open the blisters, rinse clean with water, seal with a thin epoxy that bonds to damp surfaces, then fill with a kevlar (tm) filled epoxy paste (see www.epoxyproducts.com/blister4u.html).

As far as a barrier coat - it can be done in one coat (see www.epoxyproducts.com/barrier4u.html) . But it could be that all the blisters that will form on your hull have already formed, so there is no need for an anti - blister barrier coat.

Blast the hull clean, fill/repair the blisters, apply bottom paint, put back in the water. See if there are more blisters at the next haul out.

The suggestions above, certainly isn't the money making strategy the yard wants to sell you.

Question: Gelcoat Repair

I just stripped all the bottom paint off of my 1980 csy

44. There are NO blisters, but hundreds of small gel coat pop marks where the

gel coat popped off when grinding. These marks are about the size of size of a

pencil eraser and 1/16 inch thick. I’ve also got gelcoat cracks all over. One

school of thought is to grind off all of the gelcoat now, and my bottom guy is

strongly advising not to do that, since the gelcoat is already providing 1 layer

of protection. I don’t want to spend a lot of money on barrier coat if it comes

off with the gelcoat, but I would be very happy if a product held the gelcoat

together. What is left on the boat is stuck hard. I need to know if you would

advise using a product over the gel coat to fill the cracks and pop marks, and

what product that would be. Is that product different than the barrier coat

itself? Or would you recommend stripping all of the gelcoat off. I’m not a

racer, I’m not concerned with aesthetics, I’m only concerned with hull

protection.

you probably want our epoxy cream. Unlike other thickened epoxies which pull and

tug and drag behind any putty knife, Epoxy cream goes on like a hot knife

through butter. It goes on really nice. Recently had someone with a hull full of

pencil eraser sized blisters all over. He used the epoxy cream and was so

impressed he called me to say how well it worked.

Alternately our wet dry 700 epoxy paste contains kevlar pulp and cures super

rock hard. Consider it strong and structural. But like normal thick epoxies, it

drags and pulls behind the putty knife. Consider the wet dry 700 structural and

the epoxy cream cosmetic.

Answer:

You probably want our epoxy

cream. Unlike other thickened epoxies which pull and tug and drag behind any

putty knife, Epoxy cream goes on like a hot knife through butter. It goes on

really nice. Recently had someone with a hull full of pencil eraser sized

blisters all over. He used the epoxy cream and was so impressed he called me to

say how well it worked.

Alternately our wet dry 700 epoxy paste contains kevlar pulp and cures super

rock hard. Consider it strong and structural. But like normal thick epoxies, it

drags and pulls behind the putty knife. Consider the wet dry 700 structural and

the epoxy cream cosmetic.

Question: Epoxy coating before paint on glued ply clinker dinghy?

I am building an Oughtred Guillemot glued ply clinker (lapstrake) dinghy. What are the advantages and disadvantages of epoxy coating the parts of the boat on the inside and outside that are to be painted. The ply is Oakume and is quite soft. Will a couple of coats of epoxy harden up the surface and protect it a bit from damage?

Answer:

You most certainly want to seal the plywood, especially the edges with epoxy. However you don't want to use 'regular' marine epoxy. Use a flexible epoxy paint (with some extra solvent) or a solvent thinned epoxy sealer like ESP 155 (two coats).

I am searching for an epoxy to coat the interior of a fiberglass water tank in my sailboat. This boat was built in 1979 and the tank water continues to smell of plastic even after 34 years. I expect to cut the top open and coat the interior surfaces which match the contours of the hull. Some epoxy systems recommend themselves for water tank application but usually specify the tank to be over 1000 gallons. My tank capacity is 70 gallons.

Please advise,

Thanks,

Question: Potable water approved coating for boat water tank

I am searching for an epoxy to coat the interior of a fiberglass water tank in my sailboat. This boat was built in 1979 and the tank water continues to smell of plastic even after 34 years. I expect to cut the top open and coat the interior surfaces which match the contours of the hull. Some epoxy systems recommend themselves for water tank application but usually specify the tank to be over 1000 gallons. My tank capacity is 70 gallons.

Please advise

Answer:

You will not find an epoxy coating approved for tanks less than 800-1000 gallons. Visit this site on potable water. Your options are some other kind of coating (I don't know if you can find one) or a different tank - tank liner. That said, a lot of folks do you the 800 gallon approved coatings for their personal use even if not 'officially' covered.

|

ONLINE PRODUCT CATALOGS PROGRESSIVE EPOXY POLYMERS, Inc

A COMMERCIAL - INDUSTRIAL -

PROFESSIONAL PRODUCT

You won't find these products, or products like it, in

a general purpose, mass market, consumer, DIY, box store or flashy

marketing company website.

|

|||

|

ONLINE STORE Purchase Here ------ or CALL 603 435 7199 ------ HOME PAGE |

|||

|

Marine Catalog |

|||

* home

page of marine catalog section (blue background)

|

|||

| Section One MARINE - CLEAR EPOXIES Section Two FILLERS THICKENERS ADDITIVES Section Three THICKENED EPOXIES - EPOXY PUTTIES, ETC. Section Four EPOXY PAINTS (barrier coats) Section Five URETHANES AND NON-EPOXY COATINGS Section Six NON-SKID DECK COATINGS Section Seven MARINE REPAIR PRODUCTS Section Eight MISC. MARINE PRODUCTS |

|||

|

MASSIVE BOAT HOW TO - ISSUES - HELP WEB LINK SITE |

|||

|

Residential / Commercial / DIY Catalog |

|||

* home

page of residential/commercial catalog section (brown background)

|

|||

|

Section A EPOXY PAINTS Section B FLOOR EPOXIES (regular and non-skid products), SEALERS, ACCESSORIES Section C THICKENED EPOXIES - EPOXY PUTTIES, ETC. Section D CLEAR EPOXIES Section E NON-EPOXY PAINTS COATINGS SEALERS Section F MIX-IN ADDITIVES Section G OTHER PRODUCTS Section H SURFACE PREPARATION PRODUCTS Section I MISC. ACCESSORIES |

|||

|

WEB EPOXY FLOOR ISSUES LINKS SITE --- WEB EPOXY REPAIR LINKS SITE |

|||

|

top selling favorite products for your every need Buy Talk Chat Support EMAIL or 603 435 7199

American manufactured, distributed, and sold epoxies and coatings. Your business helps small American Family Businesses - Thank You! |

|

Epoxy Crazing Notice/Warning |

|

There are two types of Marine Epoxy Vendors: 1) discount, bulk, REPACKAGERS who simple buy drums of raw resin and raw curing agent(s) from the big chemical companies and fill plastic jugs for resale; 2) FORMULATORS take the raw epoxy chemicals add to them to enhance and improve the raw "moonshine" into a "fine whiskey". Learn more repackagers/formulators. Our Basic No Blush (tm) is a formulated non blushing epoxy by Progressive Epoxy Polymers, Inc. (homepage). that includes additions for reduced brittleness and exclusive (only we have it) bubble breakers for a more perfect looking finish. Basic No Blush is the least expensive of the formulated epoxies and considered the best marine epoxy by many ex-users of the other formulated epoxies. REPACKAGED EPOXY WARNING: Over the years I have seen and had reports of non-formulated, raw resin/cure epoxies (which are extremely hard and brittle) becoming crazed with millions of cracks (like shattered safety glass) in outdoor settings that experience big changes in temperature. Formulated epoxies all seem to be 'fixed' to allow for this expansion and contraction without cracking by making them less brittle and better able to handle internal stresses. |

|

Marine Catalog ///// Stitch n Glue ///// Epoxy Only Google Search ///// Epoxy Guru Help Site ///// Marine Boat Epoxy Etc. Links |

| "I've been using the Basic No Blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future..." Patrick (comment with on-line order 9/4/07) ---- Order No Blush online |

(And less hairy than the Old Goat! and get a personal email reply

instead of a question listed on this page)

your go-to guy for two part epoxy help

Rather talk to The Professor over the telephone about your epoxy resin/paint/application issue? Our Progressive Epoxy Contact page lists our telephone number and hours available for questions and support. CLICK HERE .

Before and after Aluthane shots

(works just as well on old boat trailers too!)

aluthane moisture cured urethane and aluminum boats web page CLICK HERE

Paul-

After prepping, there was still some residual paint that was welded

on and

couldn't be removed without stripper. Since the product is designed for

'less than perfectly prepared surfaces', it didn't require messy stripping

chemicals or excessive prep work.

The Aluthane has an nice aluminum sheen and cures very hard. It has a

watery consistency and spreads easily. It filled pinhole size gaps, making

the surface airtight. I was able to mimic the original paint scheme

because of Aluthane's aluminum color. I used it as a primer and topcoat.

Aluthane made my 50 year old boat look new again!

Very satisfied, Matt

Tom wrote (10/2008):

Thanks Paul; here are a few comments on the Aluthane.

I was looking for a product to use on the 4" steel pilings on a newly constructed boat house. I wanted to

extend the life of the piles and the overall structure since the boathouse cost roughly $50K to build. Aluthane

was recommended. At the time, the water was down around three feet from normal pool so I was able to paint roughly

4 feet of the piling that was exposed. For prep, I used a simple paint scraper to smooth off the rough, loose rust

and then a wire brush. I did not put a lot of effort into preparation. Total prep time per piling was no more than

3-5 minutes. I used a 3" roller and rolled the Aluthane on. Again, very simple and quick. The

Aluthane will

run, so you do have to roll it on and smooth any runs with another quick roll over.

The results looked great. Basically a shiny aluminum look. When the lake came back up to pool, I kept watch for

any signs of deterioration and saw none 12 months after application. The water went back down even further in the

last few months, so I was able to inspect much closer and even apply the Aluthane further down the pilings. There

was absolutely no rust through with 12-15 months of submersion.

The Aluthane surpassed all expectations and I now am in a wait and see mode on how long it will last before corrosion...no signs yet. I know its not advertised for submerged applications, but I can attest that it works very well for at a minimum of one year in fresh water applications. Excellent product that requires very little prep and seems to be very effective.

DID YOU KNOW...

Epoxy coatings are used because of their

outstanding chemical resistance, durability, low porosity and strong bond

strength.

Epoxies consist of a ‘base' and a ‘curing'

agent. The two components are mixed in a certain ratio. A chemical reaction

occurs between the two parts generating heat (exotherm) and hardening the

mixture into an inert, hard ‘plastic'.

Epoxies yellow, chalk (or more commonly least lose their gloss), in direct

sunlight (UV). The yellowing can be a real problem. For pigmented epoxies select

colors that are dark or contain a lot of yellow (such as green). Even clear

epoxies will yellow and cloud up. Often epoxies are top coated with latex or

urethanes that will retain their color and attractive gloss. This is

particularly true if color coding or matching company colors is important.

Epoxies will harden in minutes or hours, but complete cure (hardening) will

generally take several days. Most epoxies will be suitably hard within a day or

so, but may require more time to harden before the coating can be sanded.

By their nature, epoxies are hard and brittle. Additives can be added to epoxies

that make them less brittle, but generally at the loss or reduction of other

positive epoxy properties such as chemical resistance.

Other clues of cheap epoxies include ‘induction time' (after mixing the two

components the mixture must sit for several minutes to ‘self cook' before being

applied).

The best time to recoat epoxy is within about 48 hours after the initial coat.

Because epoxies take days to reach full cure, a second coat applied shortly

after the first coat will partially fuse to the first coat rather than forming a

simple mechanical bond.

End users can thicken epoxy with many things, Tiny glass spheres, known as

micro-spheres or micro-balloons are commonly used. Besides thickening, their

crushable nature makes sanding the hardened epoxy easier. On the downside, they

work like tiny ball bearings, resulting is sagging and slumping. Another

thickener is fumed silica (a common brand name is Cabosil (tm)) which looks like

fake snow. About 2 parts fumed silica with one part epoxy will produce a mixture

similar in texture and thickness to petroleum jelly. Micro-spheres and fumed

silica can be combined together.

Fisheyes are areas on a painted surface where the coating literally pulls away

for the substrate leaving a coatingless void or fisheye. Often fisheyes are

caused by surface contaminants such as a bit of silicon, wax, or oil. I have

also seen them on clean plywood where epoxies paints have been used as sealers

and the problem might be due to uneven saturation (soaking-in) of the epoxy into

the wood. Surface tension plays a big part in fisheyeing. There are some

additives that can be mixed into the epoxy that will reduce surface tension.

Likewise, on wood, applying several coats of solvent thinned epoxy, instead of

one coat of unthinned epoxy, seems to work well. Applying a thick coat of epoxy

over a contaminated fisheye surface will bury the fisheye but expect the coating

to peel away in the future. As a rule of thumb, always suspect some sort of

surface contamination as the primary cause of fisheyeing.

Adding a bit of solvent to a solvent based or solvent-free epoxy is something

that most manufacturers would not officially approve of and something that might

not work with all epoxies. However, it can be done (unofficially) with the

epoxies I deal with. Adding solvent to these epoxies will: 1) thin them out; 2)

increase pot life; 3) allows them to flow off the brush/roller a bit more

smoothly; and 4) perhaps allows them to ‘soak-in', penetrate, or may be soften,

the substrate just a little bit. Not change is visible in the epoxy unless 12%

or greater solvent is added. With that amount of solvent, the epoxies no longer

cure with a glossy finish.

It is best to use epoxies with a mix ratio close to 1 to 1 as opposed to

something 4-1, 5-1, etc. because errors in the mix ratios can be more pronounced

with the latter. That said, no matter what the mix ratio is, some epoxies are

more forgiving of mix ratio errors than others. One ‘trick' of epoxy vendors

with odd or very sensitive mix ratios is to sell calibrated pumps that disperse

the epoxy components in exact amounts.

How Thick? How thick should your coating be? Economics play a major role in determining how much coating to apply. One U.S. gallon contains 231 cubic inches. That's only 1.6 cubic square feet of surface at one inch thick and that's also assuming a solvent-free product. If the product is 25% VOC (i.e. 25% solvent) then dry thickness/coverage will be 25% less. Again, assuming a 1/4 inch thick coating (250 mils) maximum coverage will still be only 6.4 square feet per gallon. A solvent-free (100% solids) epoxy coating applied at 16 mils will cover 100 square feet per gallon (note: the wall paint in your office is probably 2-4 mils). While thick coatings sound like a good idea, they use so much product that they must be made very cheaply so that coating 1,000 or 10,000 square feet can still be done at a competitive price. A high quality, fairly expensive product with a coverage rate of 100 sq. feet or more per gallon, on the other hand, will have a low enough cost per sq. foot to provide both economy and top quality.

|

"BEST" MARINE EPOXY |

|

|

SITE SPONSOR |

SITE SPONSOR |

|

|

|

garden sculptures |

stone mason for hire |

Marine Epoxy Boat Repair OLD GOAT

FAQ Q&A Guide

Web Email questions and answers on boat repair, coatings and epoxies